The Truth About Stretch in Fluorocarbon and Monofilament

* This page contains affiliate links. The Great Lakes Fisherman may earn a commission on items purchased through these links. For more on this, please click here.

There’s a dispute out there in the fishing world regarding the stretch in fluorocarbon and monofilament fishing lines. You’ll find some information stating that monofilament has superior stretch qualities over fluorocarbon. More recently, you’ll find many sources that call this a myth. So what’s the truth?

Deformity

The answer to the question of which line has better stretch capability is actually quite a bit different from answering the question of which has better stretch quality. To understand why, we need to understand just a bit about the behavior of materials.

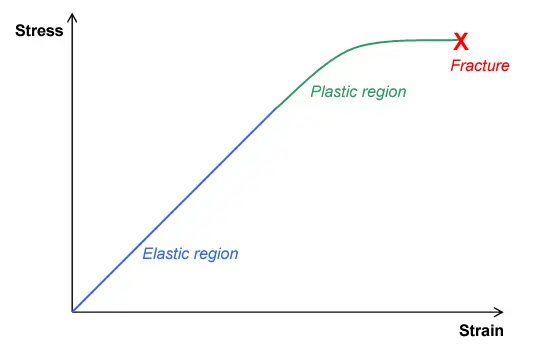

When materials are under stress they undergo deformity. But not all deformities are the same. In fact, there are actually two types of deformities that occur in stages as stress is applied to the material. These are known as elastic deformity and plastic deformity.

Elastic Deformation

Elastic deformity is quite simple. Stresses that are applied and then removed during the elastic deformity stage result in the material returning to its original shape and size. This deformity is effectively temporary. We see this in everyday life all the time. Just think about the stretching of a rubber band. By applying stress to the rubber ban, it stretches. In doing so, we are deforming it because we’re changing its size and shape. The usefulness of a rubber band is in its ability to return to its original size and shape following that deformity and its ability to do this is due to the inherent properties of the rubber itself.

Plastic Deformation

In contrast, plastic deformity is permanent. The reason for this is that there is damage being done to the molecular structure of the material. A great example of plastic deformity occurs when plastic wrap is stretched. The wrinkles that remain in the plastic wrap after being stretched are signs of permanent damage done to the plastic material that make up the plastic wrap. When the stress on the material becomes large enough and enough damage has been done to the molecular structure of the material, failure occurs and the plastic tears.

Stress vs. Strain

The above graph depicts these three phases of stress and strain. Note that in the elastic phase, the relationship between the stress and strain is linear. Once the strain reaches a certain point, the stress begins to slow. This is due to the breaking of molecular bonds within the material or what we call damage. As the strain continues, we eventually reach the failure point of the material. The important thing to note is that this curve is unique for each material. For some materials, the elastic region is relatively small while the plastic region is much larger. For others, the reverse is true. So what does all of this mean when it comes to fishing line?

While fluorocarbon does stretch quite a bit, it does much of this stretching in the plastic deformation region. This means that although it is stretching, it is also permanently weakening throughout the majority of its stretch. The problem with this is that, while fishing, we have no way of knowing when this happens. Conversely, monofilament line stretches almost entirely through elastic deformation and therefore doesn’t weaken like fluorocarbon. This means that it will return to its original size and shape with little to no permanent damage.

Conclusion

So to answer the questions we posed at the beginning of this video, while both lines will ultimately stretch quite a bit, unlike monofilament line the fluorocarbon often ends up weaker once it has stretched, making it more likely to break in the future. This is just one of the reasons that fluorocarbon is a great choice for leader material but loses its appeal as a main line.